Application:

Metal Fabrication

Maintenance and Repair

Auto Bodye

Precision fabrication

Heavy fabrication

Pipe and tube fabrication

Aerospace

Aluminum ship repair

Anodized aluminum fabrication

Processes:

DC TIG (GTAW)

AC TIG (GTAW)

MIX TIG (GTAW)

Pulsed TIG (GTAW-P)

Stick (SMAW)

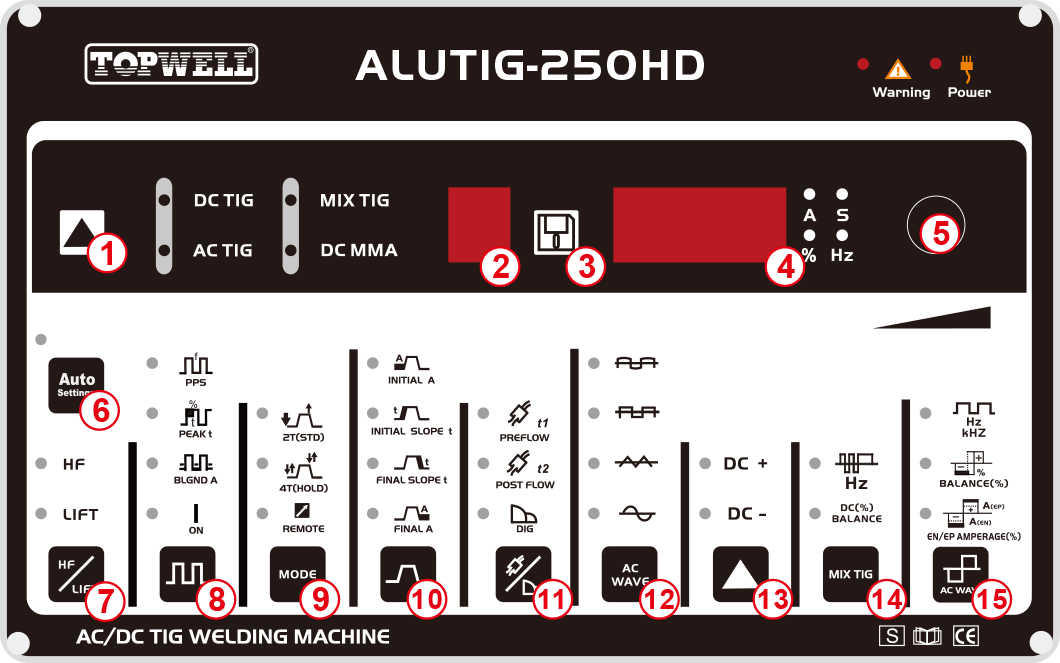

General View Of Control Panel

1. Welding Process

DC TIG / AC TIG

MIX TIG / DC MMA

2. Memory Display

3. Memory

4. Ammeter/Voltmeter Display

5. Encoder Control

6. AC Waveshape types

7. Arc Ignition type

HF Impulse

LIFT Arc

8. Pulser Control

Pulse Frequency: 0.2Hz~200Hz

Pulse Width (Ratio): 1~100%

Base Current: 5A~250A

Peak Current: 5A~250A

9. Mode

2T(STD) / 4T(HOLD) / REMOTE

10.Sequencer Control

Arc-starting Current: 10A~160A

Crater-filling Current: 5A~160A

Current Up-slope Time: 0.1S~10S

Current Down-slop Time:0.1S~15S

11. Pre-Gas Time: 0.1S~10S

Flow-Gas Time: 0.1S~15S

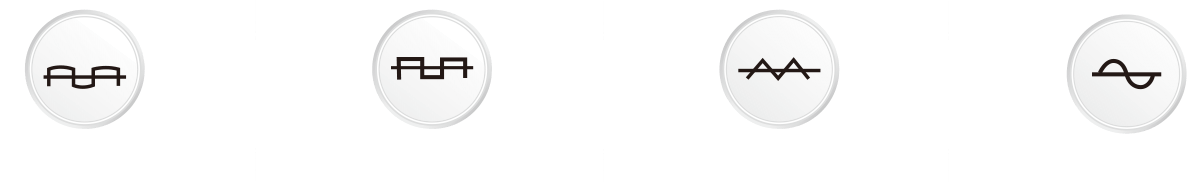

12. AC Waveshape types

Advanced Squarewave / Soft Squarewave

Triangular Wave / Sine Wave

13. Arc Ignition Polarity: DC+ / DC-

14. MIX TIG

MIX Frequency: 0.1Hz~5Hz

DC Balance: (%) 10~90

15. AC Waveshape

AC Frequency Range: 20Hz~200Hz

AC Clean Width (AC Balance): +40~-40

AC Clean Ratio (AC Bias) %: +30~-50

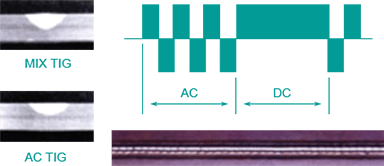

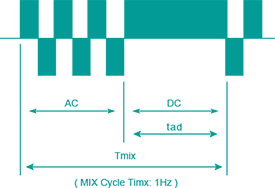

MIX TIG Control

Features of MIX TIG:

The AC current can get a very good clearance, and DC current can get a deeper penetration. Use the MIX TIG we can get an excellent Arc Concentration, can be carried out the excellent welding performance from thin to thick plate.

1) Nice weld appearance, deep penetration.

2) Excellet Arc Concentration..

3) Substantially reduce the electrode consumption.

MIX TIG Frequency (Hz):

the cycle time of MIX

TIG in 1 second. Adjustable range: 0.1-10Hz..

MIX TIG Balance (DC) %:

DC Balance (%) = (tad/Tmix) x 100

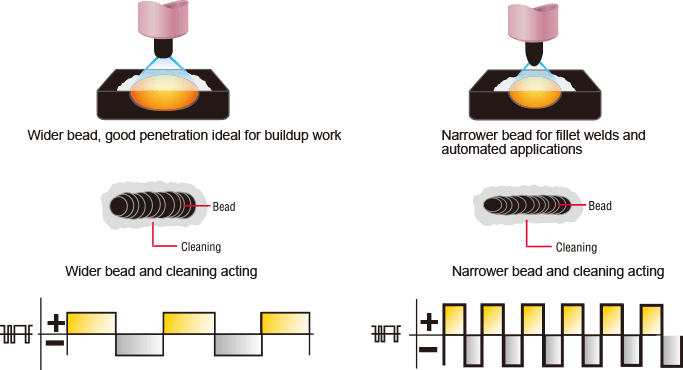

AC Waveshape Controls

AC Frequency control

Controls the width of the Controls the width of the arc cone.

Increasing the AC Frequency provides a more focused arc with increased directional control.

Note: Decreasing the AC Frequency softens the arc and broadens the weld puddle for a wider weld bead.

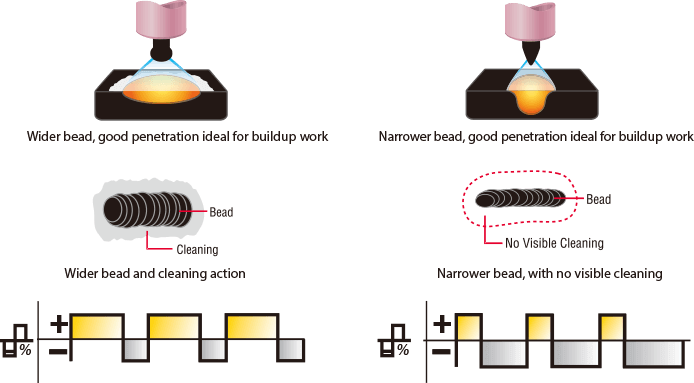

AC Balance Control

Controls arc cleaning action. Adjusting the % EN of the AC wave controls the width of the etching zone surrounding the weld..

Note: Set the AC Balance control for adequate arc cleaning action at the sides and in front of the weld puddle. AC Balance should be fine tuned according to how heavy or thick th eoxides are.

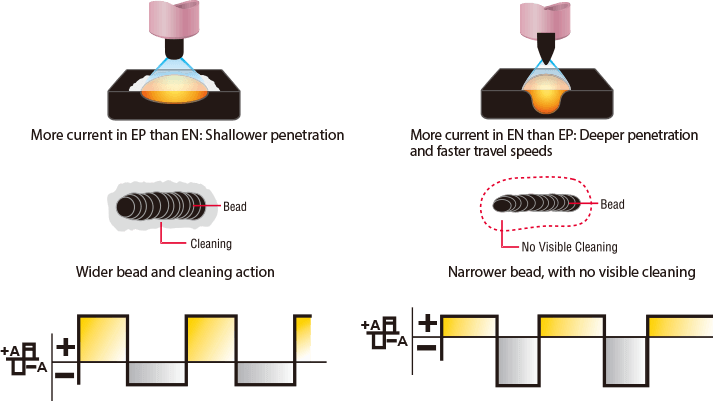

Independent AC Amperage Control

Allows the EN and EP amperage values to beset independently. Adjusts the ratio of EN to EP amperage to.

precisely control heat EN amperage controls the level of penetration, while EP amperage dramatically effects the arc cleaning action along with the AC Balance control.

AC waveshape options

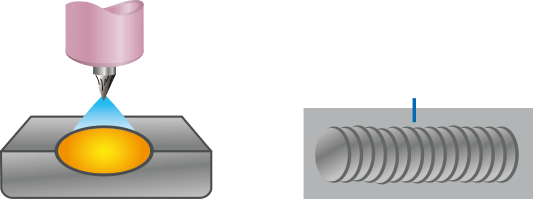

Pulsed TIG Controls

The Pulsed TIG function switches the amperage from a high(peak) to a low(background) at a set rate(PPS). Pulsing can reduce heat input by lowering the average amperage,increasing control of the weld puddle, penetration and distortion. The following parameters can be adjusted for desired results:

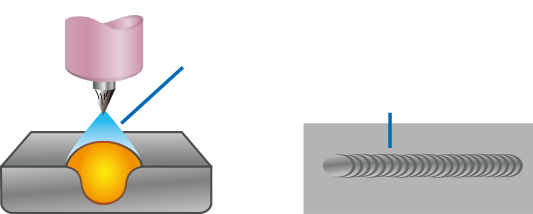

Low-Speed Pulse

1 to 10 pulses per second(PPS) will produce a distinct ripple pattern in the weld bead. Can be used to time filler addition,reduce distortion and improve control.

High-Speed Pulse

100 pulses per second(PPS) and higher helps to focus the arc for increased stability, penetration an d travel speed. Increased puddle agitation improves weld microstructure.

LET'S STAY IN TOUCH

Get updates on sales specials and more

FOLLOW US

We want to hear from you!

Copyright © 2022 HANGZHOU TOPWELL TECHNOLOGY CO.,LTD. | 浙ICP备2022006748号